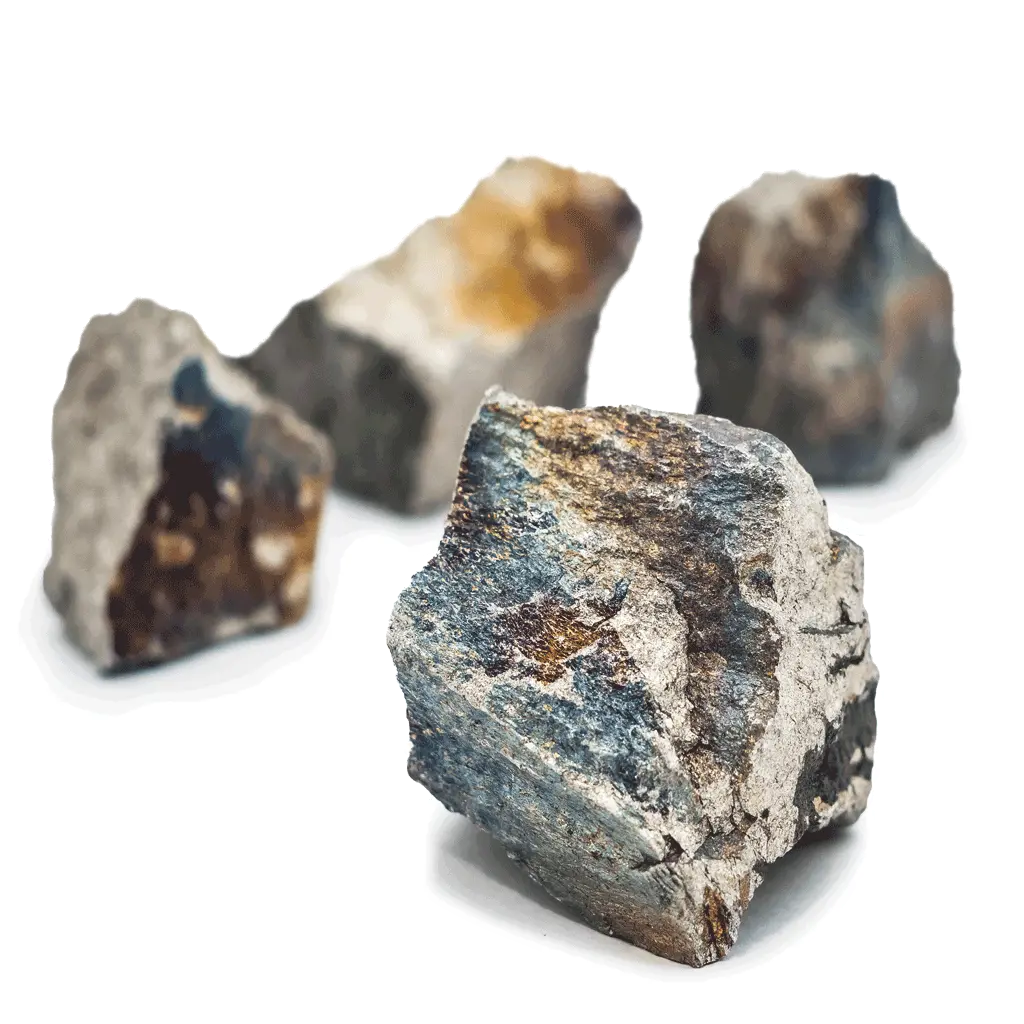

Iron concentrate:

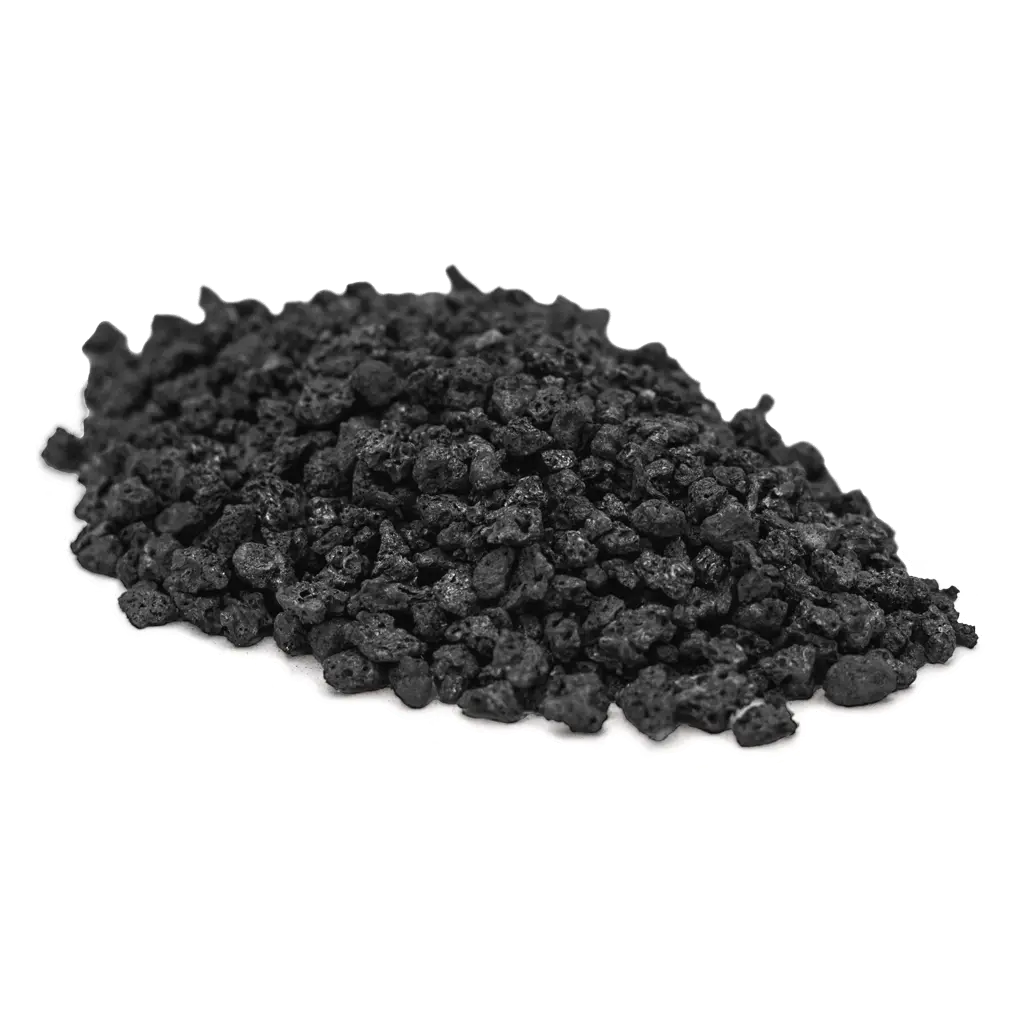

Iron concentrate is a type of iron ore that has been processed to remove impurities and increase Iron content. It is made up of minute, dry particles of pure Iron. Iron concentrate is useful in applications where high surface areas are desired, such as water treatment and fuel cell and solar applications. Iron concentrate is also used to produce steel and other iron-based products.

Some of the advantages of iron concentrate over iron ore:

- Iron concentrate has a higher iron content than iron ore, which means it can produce more steel with less raw material. • Iron concentrate has lower levels of impurities such as Al 2 O 3, crystal water, and harmful elements than iron ore, which can improve the quality of the sinter and reduce the slag formation in the blast furnace.

- Iron concentrate can enhance the melt formation and bonding mechanisms during sintering, which can improve the sinter strength and reducibility

How is iron concentrate produced?

Iron concentrate is produced by processing iron ore to remove impurities and increase iron content. The process involves crushing, grinding, magnetic separation, and flotation. The iron concentrate is then used to make sinter or pellets, which are agglomerated forms of iron ore that can be used in blast furnaces or direct reduction processes.

Applications

- It is used for sintering and blast furnace production, which are the main methods of ironmaking.

- It is used for pellet production, which is an alternative method of ironmaking that uses less energy and emits less CO2

- It is used for water treatment and fuel cell and solar applications, where high surface areas of iron are desired.

- It is used for virus concentration and precipitation, where iron flocculation can capture and isolate viruses from water.