Graphite Electrodes:

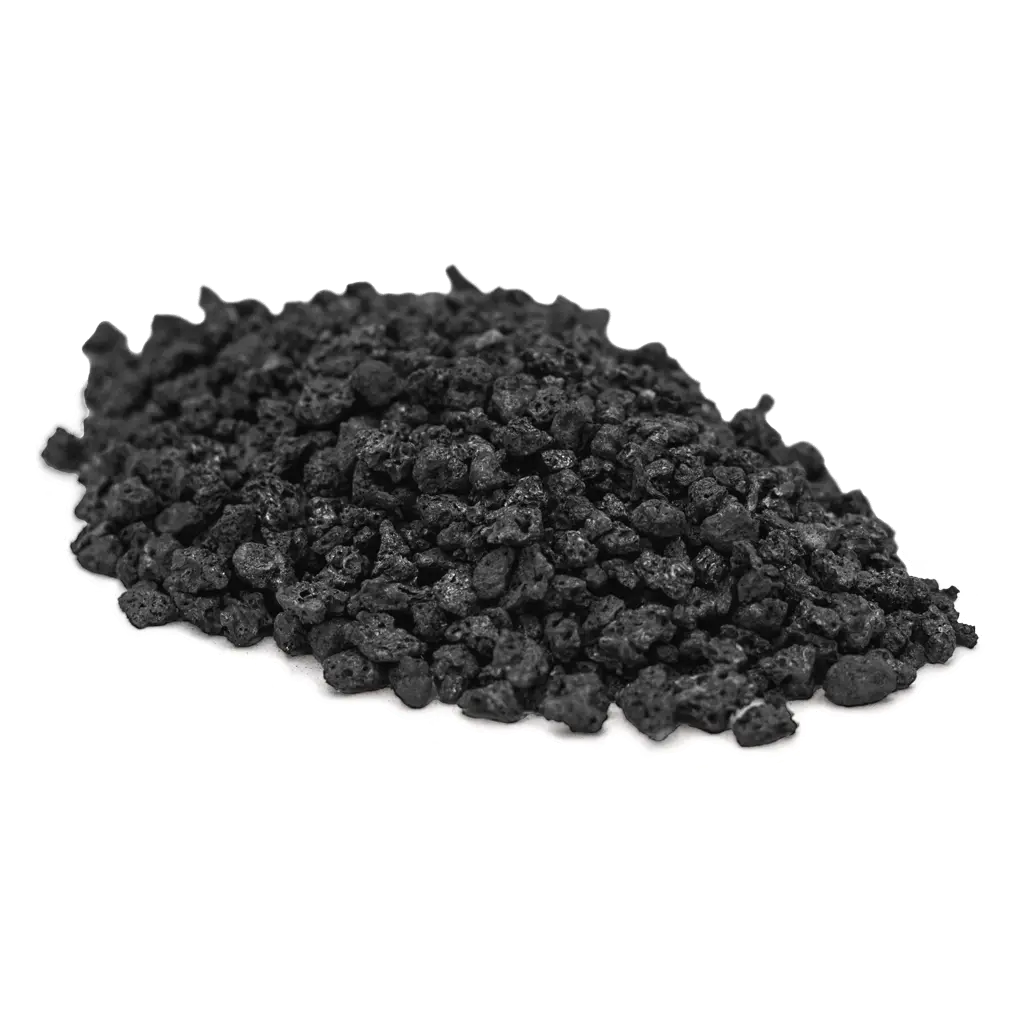

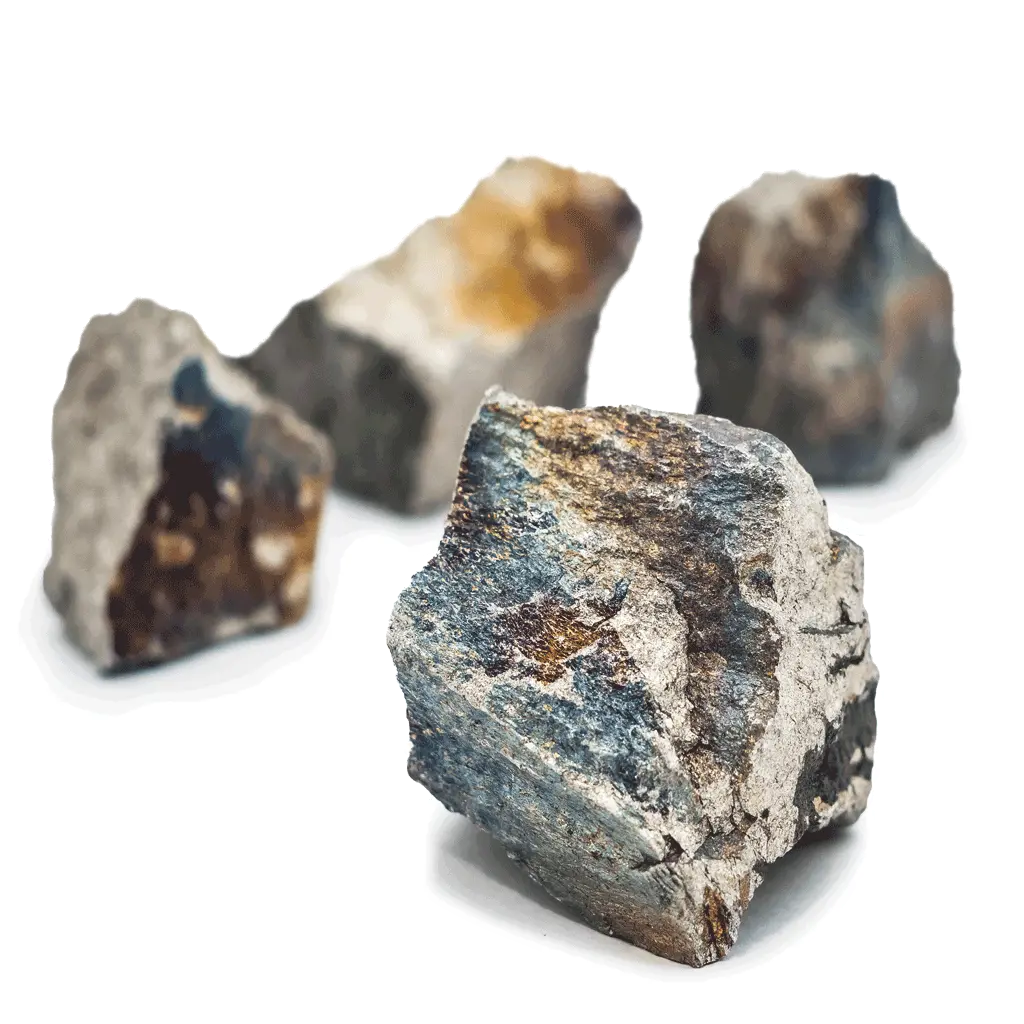

Graphite electrodes are electrodes made of petroleum coke, coal tar pitch, and some additives, and are shaped by extrusion, baking, impregnation, graphitization, and machining and are utilized in applications that require significant levels of electrical conductivity and tolerance to high temperatures. These electrodes are prominently used in electric arc furnaces (EAF) to liquefy scrap iron and steel, and on rare occasions for direct-reduced iron. Graphite electrodes are also used to refine steel in ladle furnaces and in other smelting processes.

Graphite electrodes have some advantages over other types of electrodes, such as low cost, high-temperature resistance, good thermal shock resistance, low electrical resistance, and easy machining.

Different Grades of Graphite Electrode

- RP graphite electrodes are the lowest grade of graphite electrodes, with a density of 1.55-1.65 g/cm3, a resistivity of 7.5-8.5 μΩm, a thermal expansion coefficient of 2.2-2.6 x 10-6 /K, an ash content of 0.3-0.5%, and a mechanical strength of 7.5-13 MPa. RP graphite electrodes are suitable for electric arc furnaces with low power or short arc operation.

- HP graphite electrodes are the intermediate grade of graphite electrodes, with a density of 1.65-1.75 g/cm3, a

resistivity of 5.5-6.8 μΩm, a thermal expansion coefficient of 1.6-1.9 x 10-6 /K, an ash content of 0.2-0.3%, and a mechanical strength of 9.5-15 MPa. HP graphite electrodes are suitable for electric arc furnaces with medium power or long arc operation.

- SHP graphite electrodes are high-grade graphite electrodes, with a density of 1.70-1.80 g/cm3, a resistivity of 4.5-5.8 μΩm, a thermal expansion coefficient of 1.5-1.8 x 10-6 /K, an ash content of 0.2%, and a mechanical strength of 10-18 MPa. SHP graphite electrodes are suitable for electric arc furnaces with high-power or ultra high-power operation.

- UHP graphite electrodes are the ultra-high grade of graphite electrodes, with a density of 1.75-1.85 g/cm3, a resistivity of 4.0-5.0 μΩm, a thermal expansion coefficient of 1.1-1.4 x 10-6 /K, an ash content of 0.2%, and a mechanical strength of 11-20 MPa. UHP graphite electrodes are suitable for electric arc furnaces with ultra high power or extreme conditions operation.

Applications of Graphite Electrodes

Graphite electrodes have various applications besides steelmaking, such as:

- Industrial silicon furnaces, yellow phosphorus furnaces, corundum furnaces, etc., as conductive electrodes.

- Miniaturized biofuel cells and bio-batteries, as high-power biocathodes.

- Sheet metal welder for almost any metal, as a soldering iron.

- Electrochemical sensors and biosensors, as disposable probes.

How graphite electrodes are used in electric arc furnace steelmaking:

Electric arc furnace (EAF) steelmaking is a process that uses electric current to melt scrap iron and steel, and sometimes direct-reduced iron (DRI), in a furnace. The electric current is generated by graphite electrodes, which are inserted into the furnace and connected to a power supply. The graphite electrodes act as conductors of electricity and also as sources of heat.

The role and function of graphite electrodes in the process are:

- To transfer the electrical energy from the power supply to the steel melt in the furnace, creating an electric arc between the electrodes and the scrap metal. The electric arc generates temperatures of up to 3000°C, which is enough to melt the scrap metal and form molten steel.

- To control the temperature and chemical composition of the molten steel by adjusting the current, voltage, and electrode position. The graphite electrodes can also be used to inject

oxygen, carbon, or other additives into the molten steel to modify its properties and quality.

- To withstand the high temperatures and corrosive conditions in the furnace without melting or breaking. The graphite electrodes have high thermal conductivity, low thermal expansion coefficient, high mechanical strength, and low electrical resistance, which make them suitable for EAF steelmaking.