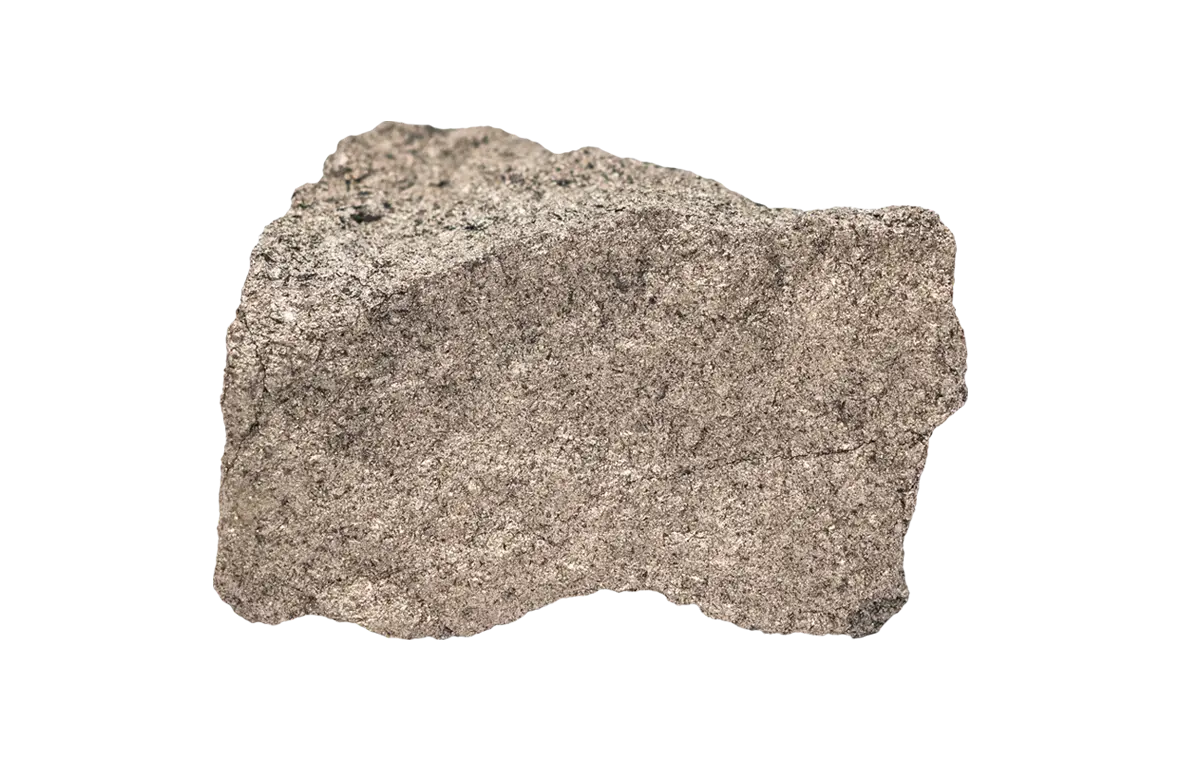

What is Ferro Silicon?

Ferro Silicon is an iron and silicon alloy that typically contains 15% to 90% of silicon by weight. This alloy has a high concentration of iron silicides and can be made through the reduction of silica or sand in the presence of iron and coke. Ferro Silicon is often used as a source of silicon to reduce metal oxides and deoxidize steel and other ferrous alloys.

How is Ferro Silicon made?

Ferro Silicon with low silicon content (up to about 15%) is made in blast furnaces lined with acid fire bricks and Ferro silicon with high silicon content (up to 90%) is made in electric arc furnaces. The Ferro silicon production process includes three steps: raw materials are put into the furnace; coke and silicon iron ore react under electrical heating; and melting Ferro silicon flows out of the furnace and every production cycle takes about 24 hours.

Some advantages of Ferro Silicon over pure silicon

- Ferro Silicon has a lower melting point and a higher density than pure silicon, which makes it easier to handle and transport

- Ferro silicon is cheaper and more abundant than pure silicon, as it can be produced from low-grade and low-cost ferrosilicon

- Ferro silicon can be used as a basis for the manufacture of prealloys like magnesium ferrosilicon (MgFeSi), used for

the production of ductile iron. Pure silicon cannot form such alloys with other metals.

- Ferro Silicon can be used as a silicon source to reduce metals from their oxides and deoxidize steel and other ferrous alloys. Pure silicon is not suitable for these applications because of its high reactivity with oxygen.

Applications of Ferrosilicon

- Ferro silicon is utilized in various ways in the cast iron industry. It can act as an inoculant and spheroidizer, preventing carbides from forming in iron and promoting graphite precipitation and spheroidization.

- It serves as a reducing agent in ferroalloy production, where high silicon Ferro silicon with low carbon content and chemical affinity with oxygen is employed to produce medium and low-carbon ferroalloys.

- Also, it is used in mineral processing, electrode manufacturing, chemical industry, etc. For example, fine or atomized ferrosilicon powder can be utilized as a suspension phase in the mineral processing industry.

- It can act as a source of silicon, helping in the reduction of metals from their oxides and the deoxidation of steel and other ferrous alloys. This prevents carbon loss from molten steel and enhances its strength, hardness, and elasticity.

- Ferro Silicon also forms a basis for creating prealloys, including magnesium ferrosilicon (MgFeSi), which is

essential to producing ductile iron. Magnesium Ferro Silicon (MgFeSi) contains between 3 and 42% magnesium and small quantities of rare-earth metals, which help in the generation of nodules, hence giving ductile iron its flexible property.