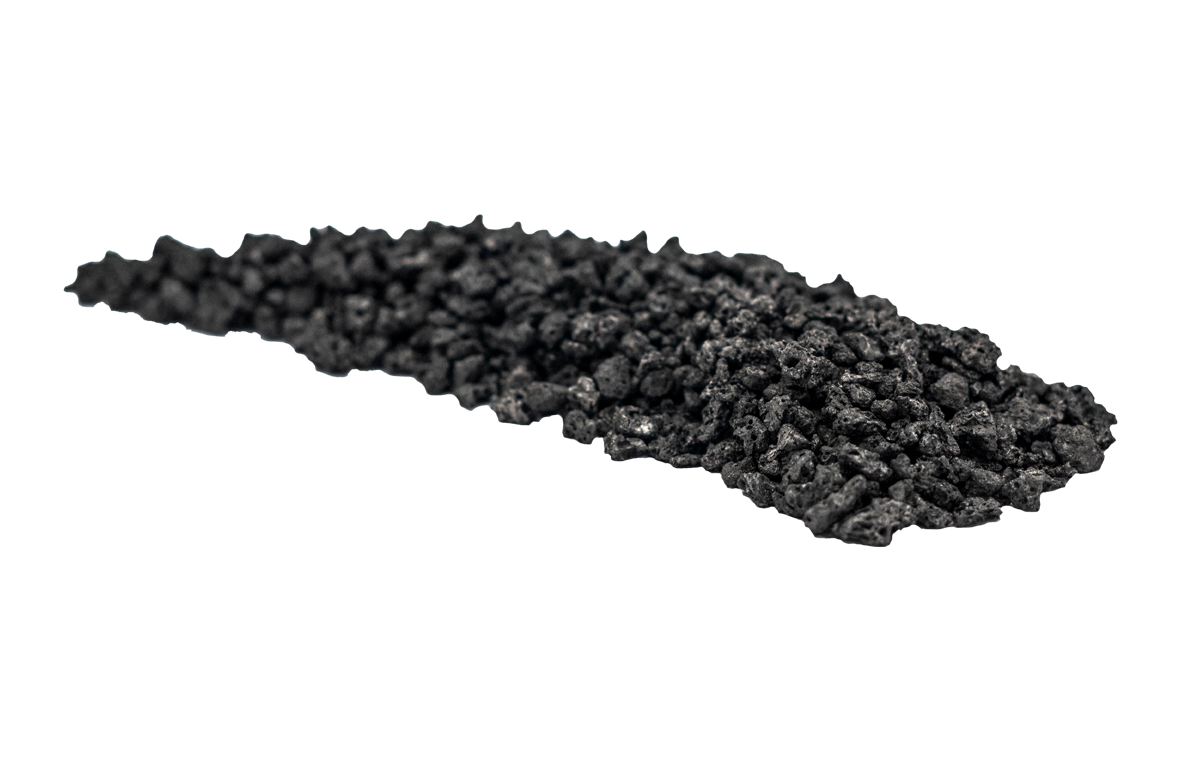

Calcined Petroleum Coke

Calcined petroleum coke or CPC, is derived from raw (green) petroleum coke at temperatures greater than 1200°C. This process removes moisture and volatile matter from GPC and improves its physical and chemical properties. There are various methods to produce CPC, such as using a rotary kiln, hearth, and vertical shaft technologies.

Calcining Technologies Used by the Industry to Make CPC

- Rotary kiln calcining: The technology that is widely used in the Western world involves introducing green petroleum coke into a cylindrical kiln which is long and rotates slowly. The coke is heated at a regulated speed and the calcined coke eventually comes out of the kiln. The coke is then screened and cooled before it is shipped or kept for storage.

- Shaft calcining: The process of shaft calcining is extensively used in China as the primary technology. It comprises feeding green petroleum coke into vertical shafts with controlled airflow and multiple heating zones. After the process is complete, the calcined coke is discharged at the bottom of the shafts, cooled, screened, and then dispatched for shipping or storage.

- Fluidized bed calcining: Fluidized bed calcining is a modern process in which hot air is used to fluidize green petroleum

coke particles in a reactor. The calcined coke is then isolated from the air stream and undergoes a cooling and screening process before being dispatched or stored.